Thanks, Donovan - same to all.

Been a little busy with the medicos and new fusion experiment design, but I just had to kind of take a little fun break....

Today was nice weather (high 50's, sun, no wind) and...

- Some days, the plan just comes together

- The gun I'm building. 6.5 Swede, Mauser 98 action, custom butchered stock, Leupold scope.

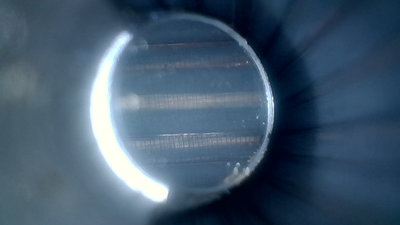

This is the 6.5 Swede bull barrel, a varmint sort of load, 95 gr Hornady bullet, moly coated here, shot about half an hour after shooting some lead bullets that left the barrel cleaner than patches and solvent would...(lee liquid alox lube does that). Borescope showed moly about halfway down the barrel, copper after that, and toolmarks are still there from manufacture. Maybe I just need to shoot a lot more. By the deposits on the grooves, it looks like this cheapo A&B barrel actually does have a slight taper down the length - the right one. Either design or I just got lucky.

- Got toolmarks?

This is not as good as I expect to get eventually, but hey, it ain't bad - varmints beware - we're at minute of field mouse. But gosh darnit - the hole isn't round and is bigger than .264. This load has an insane jump to the lands of around 100 mils, holy cow. (Edit - 143 mils, measured - I wanted to know so as to make more of these) Run of the box winchester brass - I'm working on some super brass prep stuff, induction annealer, wet tumbling with SS media and my own chemistry, plus weight segregation and the other stuff as usual. I'm full length sizing all this, as I've cut the chambers on the two guns I'm working on to be a pretty tight fit with brass "at spec" so no foolery with fireforming/neck-only-sizing needed.

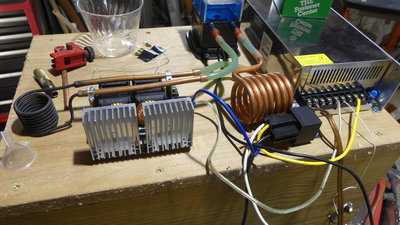

Here's some shots of the toys.

- I came here to time and control things, and I'm all out of 555s.

- Induction annealer, around 1kw. Custom coil of small tubing. The big one is just to radiate heat, it came with the source. I still have to build the solenoid trap door to drop the hot brass when it's done.

Side note - I now see why they forbid doping with Metoprolol in the Olympics. Wow, the old hold just settles right down, as if there's no heartbeat. I was actually holding a bit better than the group shows, without really trying, and I'm not that good normally.

As for my fusion experiment, I've decided to make a fusor in a fusor, or in other words, stick another piece of pipe in there to be the outer electrode (it'll have to be a little smaller diameter so as to fit through the door) and drive that with RF + the B+ voltage from the RF stage - And then use the center electrode (grid) to push in some negative DC and to measure the effect of ion presence at varying amounts of ions/gas pressure vs the other speeds and feeds. This avoids having to measure on the same wire I'm driving, and the need for insane coupling capacitors or super broadband isolation transformers - I already have a probe that I trust that is broadband. Should be fairly easy to compensate out the expected capacitive coupling from the RF to the grid, and while the RF source will have to also drive the capacity between the pipe and the vacuum tank, that's no big deal and I'll be comparing what is actually on the pipe with what's actually on the grid (with a known series impedance between the DC supply and the grid). It'll take awhile to build this, but as far as I know, I have all the parts, just need to do some more fab, make another probe, and get it all installed in the big tank that at least has a great vacuum setup.

I'd built and tested a really great ion source back when I thought I could do this on the #2 system, before it became too rotten vacuum wise to work where I want to work. It has a greater than 10k gauss magnet setup with an ejection hole for ions, and draws significant current - and creates lots of ions, even at e-6 mbar, so it'll do here. I just have to keep the power input to it down to keep from heating up the crazy big hollow NdFeB magnets.

So, I at least have a plan for times in between surgeries if I'm up to getting into the shop.