Heres a little video I shot from my phone of some random stuff at the Oregon Steam Up last weekend:

Though you really should go to the youtube site and watch it in its HD glory. Click on the video twice.

Oregon Steam Up

Forum rules

Here, you can discuss anything (well, anything legal and not offensive) you want to. Use this for gassing about any half-baked theories, general getting to know one another, and other things that as someone once said, should be forgotten after awhile. This sub forum is set to auto-remove threads that haven't been posted on for a couple weeks, emptied like the office trash can. Almost anything goes here, the idea being to keep the other forums and threads more on topic but in a maximally friendly way. If anything actually worthwhile should wind up here, let me know and I will make it immune from being removed.

Here, you can discuss anything (well, anything legal and not offensive) you want to. Use this for gassing about any half-baked theories, general getting to know one another, and other things that as someone once said, should be forgotten after awhile. This sub forum is set to auto-remove threads that haven't been posted on for a couple weeks, emptied like the office trash can. Almost anything goes here, the idea being to keep the other forums and threads more on topic but in a maximally friendly way. If anything actually worthwhile should wind up here, let me know and I will make it immune from being removed.

25 posts

• Page 1 of 3 • 1, 2, 3

Re: Oregon Steam Up

Nice stuff! We have a yearly huge flea market in a couple towns over -- like 100+ acres. One of the big attractions to me is that some of the vendors

bring stuff like this and demo it for making, say, ice cream, or churning butter. The "more modern" have old John Deere skip-cycle diesels, which are also way cool.

But, being an engineer, I can't see myself just duping one of these old designs (though I know there are a bunch of fanatics who do), but designing a more modern

steam engine -- they did a lot with what they had (some of the valving things on a Corliss are amazing, as are some locomotive schemes), but where they had hide

for piston rings/packing, we've got teflon and the like. Not to mention better bearings and stainless steel etc.

In fact, air-hydraulic cylinders....which handle these kind of conditions really well. If I were going to play with steam, I'd be making a radial, self-starting 3 cylinder double-action

machine, I think. Something I could actually use for alternative power (heat with sun, firewood, whatever). Use a permanent magnet many-pole alternator (so it will work going slow),

and bingo, I got charge in my batteries off any heat source I can muster. The only thing that has stopped me making one so far is the trickery needed on the valving and plumbing.

Not that I couldn't make one work, but if you're assuming say 2-3 hp and fairly small cylinders (for higher rpm) then lost volume in the valving seems to kill you efficiency wise, and I've not figured out a way to really minimize that that makes me go "that's it".

I suppose that a truly trick design there would be compound and use the steam output from one stage on another one, probably larger Cu In per stroke?

All kinds of interesting stuff comes to mind there -- most of the parts (cylinders) are real cheap, surplus. And the tricky parts to machine (cranks, valve and links) might last a long time

in service?

Just a thought. My spec is:

Gotta be self starting.

Gotta handle wide range of heat/steam inputs without disaster.

Gotta be efficient.

Of course, here in the mountains, it's even possible to dream that the condenser would be so far uphill that gravity could be the boiler feed pump

and you could use a closed cycle....

bring stuff like this and demo it for making, say, ice cream, or churning butter. The "more modern" have old John Deere skip-cycle diesels, which are also way cool.

But, being an engineer, I can't see myself just duping one of these old designs (though I know there are a bunch of fanatics who do), but designing a more modern

steam engine -- they did a lot with what they had (some of the valving things on a Corliss are amazing, as are some locomotive schemes), but where they had hide

for piston rings/packing, we've got teflon and the like. Not to mention better bearings and stainless steel etc.

In fact, air-hydraulic cylinders....which handle these kind of conditions really well. If I were going to play with steam, I'd be making a radial, self-starting 3 cylinder double-action

machine, I think. Something I could actually use for alternative power (heat with sun, firewood, whatever). Use a permanent magnet many-pole alternator (so it will work going slow),

and bingo, I got charge in my batteries off any heat source I can muster. The only thing that has stopped me making one so far is the trickery needed on the valving and plumbing.

Not that I couldn't make one work, but if you're assuming say 2-3 hp and fairly small cylinders (for higher rpm) then lost volume in the valving seems to kill you efficiency wise, and I've not figured out a way to really minimize that that makes me go "that's it".

I suppose that a truly trick design there would be compound and use the steam output from one stage on another one, probably larger Cu In per stroke?

All kinds of interesting stuff comes to mind there -- most of the parts (cylinders) are real cheap, surplus. And the tricky parts to machine (cranks, valve and links) might last a long time

in service?

Just a thought. My spec is:

Gotta be self starting.

Gotta handle wide range of heat/steam inputs without disaster.

Gotta be efficient.

Of course, here in the mountains, it's even possible to dream that the condenser would be so far uphill that gravity could be the boiler feed pump

and you could use a closed cycle....

Posting as just me, not as the forum owner. Everything I say is "in my opinion" and YMMV -- which should go for everyone without saying.

-

Doug Coulter - Posts: 3515

- Joined: Wed Jul 14, 2010 7:05 pm

- Location: Floyd county, VA, USA

Re: Oregon Steam Up

I think steam engines really hit their peak efficiency in their heyday with the triple expansion engines and turbines. The triples suck out about every bit of energy left in the steam. Every conversion of energy you loose energy, from fuel, to steam, and change that to mechanical motion. IC engines are just so much more efficient.

I have been working on a small model hit-and-miss. Someday I will get back to work on it.

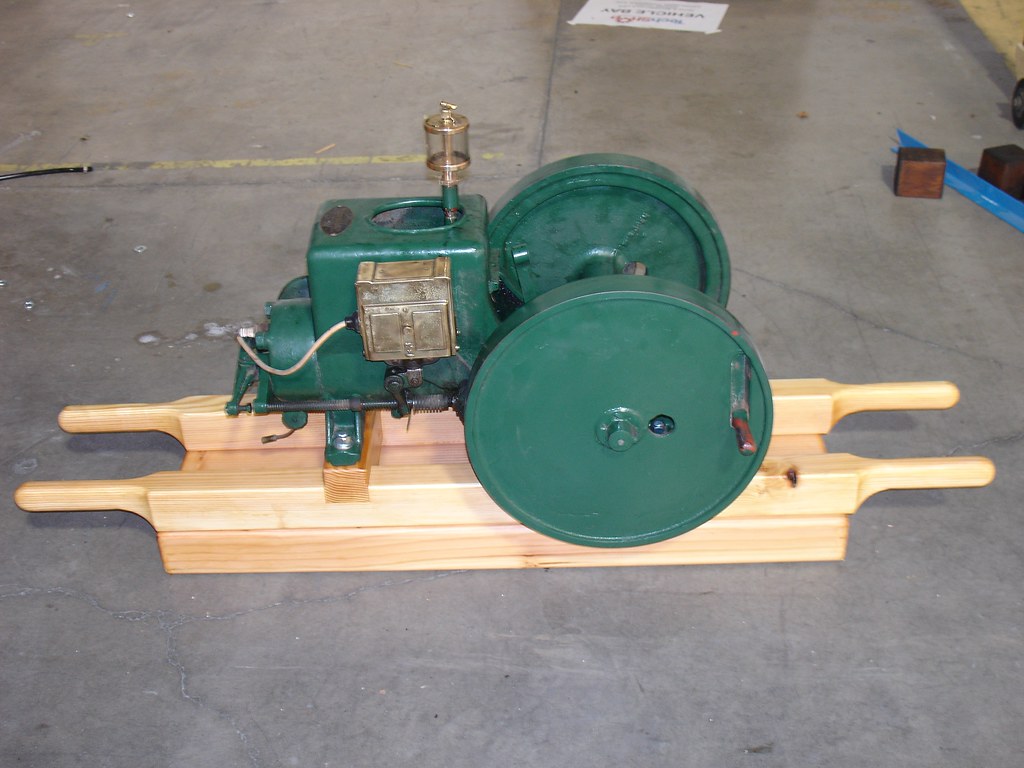

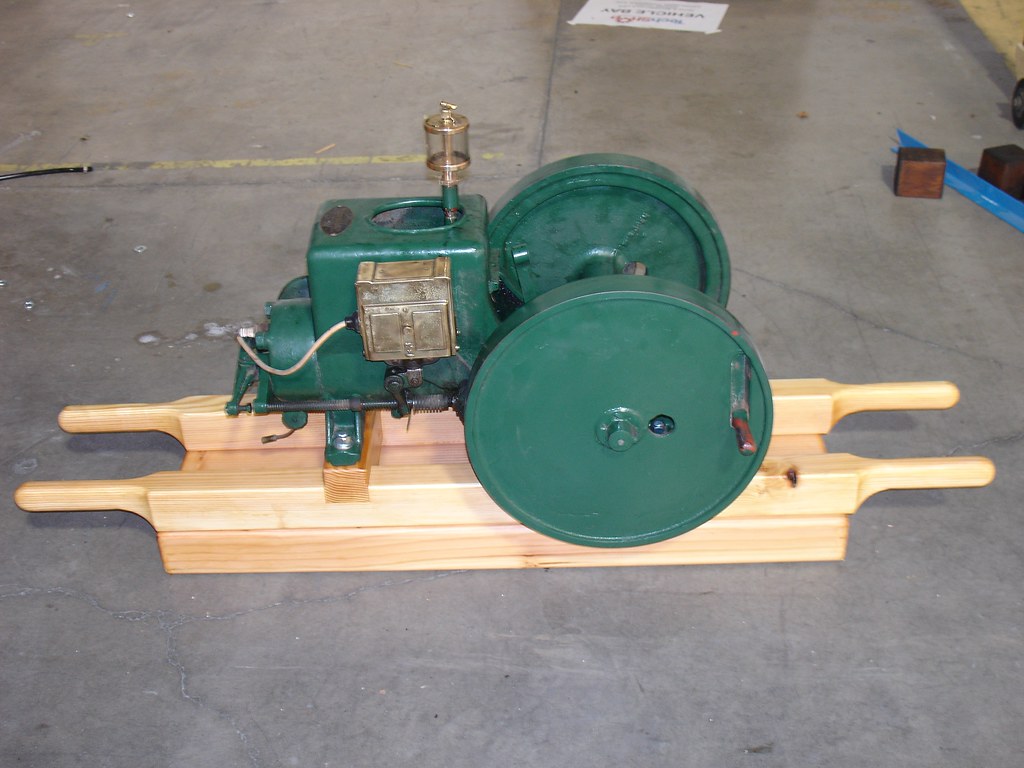

Heres a real one I have, 1-1/2HP, Sattley Montgomery Ward, 550 RPM. Made somewhere mid to late 20's.

This is a steam gauge, used to time the valving of a steam engine and to tune it. It shows pressure vs. piston position. A must have item for any steam mechanic:

I have been working on a small model hit-and-miss. Someday I will get back to work on it.

Heres a real one I have, 1-1/2HP, Sattley Montgomery Ward, 550 RPM. Made somewhere mid to late 20's.

This is a steam gauge, used to time the valving of a steam engine and to tune it. It shows pressure vs. piston position. A must have item for any steam mechanic:

- Jerry

- Posts: 573

- Joined: Sun Jul 18, 2010 12:07 am

- Location: Beaverton, OR

Re: Oregon Steam Up

Oh, man, we're going to have to swap some things around this, or me get busy on the scanner. I have a few really old "engineer" books from the period that get into considerable detail on things like this -- it was all there was at the time (but the schemes for self-feeding carbons into lamp arcs were a close second in coolness). In some ways I'd say those guys were at least as smart as we, considering what they managed with crummy materials. I also have some machine-shop books from pre and post WW I that show how to get sub mil accuracy out of machines that we'd put in a museum and not consider refurbishing for actual use. And I use some of the tricks for getting better results out of some of the modern Chinese machines I own today.

The sound of those hit and miss engines is just so neat....they are a big attraction at the flea market in Hillsville (this is two-three blocks wide by a few miles long, and you cannot see it all in a day).

Turbines can do better than pistons -- these days they are pushing the high 40% range from calculated BTU in coal to output electricity -- but might be past our speed to make at that level (many stages with interstage reheats, first stage supercritical). However, a 2 stage design with the first stage pelton-wheel like, and the second (and any further stages) your basic turbo fan is fairly decent, and by controlling how many nozzles are open can handle a wide range of inputs -- I'd been looking at that too. As in, could one design a turbine with blades cast from melted down beer cans? Yes, these would wear out all too quick, but -- considering where they'd be going, maybe not a problem if the basic design makes it easy to keep up. A lot of people in some places have plenty of time, but not a lot of good toolage, and I've seen quite a lot of ingenuity from there, from cars made almost all out of scrap metal to even transformers made of cut up sheet metal for the cores (from back when beer cans were iron). If you can make them a design where the only parts that wear out can be made by them -- that's gold for all concerned.

No question IC engines are better -- but this is because they use a better fuel too, can't burn logs or coal in one. My purpose built backup generator for the solar system is sweet on that level. It uses a 6.5 hp high compression Honda engine driving the generator from a WWII Spitfire. After many thousands of hours, the generator brushes still look new -- I couldn't believe it when I tore it down "just in case" -- we must have really wanted to win that war. But also, the IC engines fail easier....and need two special fluids to work, not junk you just find laying around.

In my case, BTU's are nearly free anyway -- we have a large woodlot and a few tons of "thermal security" in the form of coal out back. Not to mention plenty of sun much of the time. But can't use any of those in an IC engine, hence the interest in something else. Particularly, things that work in sun-free February. Electricity from an IC engine is a buck a kwh when you consider wear along with oil and fuel.

What I was looking at was for power generation, simple and cheap, for myself and for parts of the world that need this kind of thing -- cheaper than my solar stuff, and possible for an idiot to run and repair. Safety in the event of a little over-firing would be a pretty big deal, which is why I mentioned that, along with self starting (for solar dynamic heat input). Can't count on a microprocessor control for 3rd world kinds of apps. This actually makes the turbine look best, if relief valves control the extra input nozzles to keep boiler pressure in range no matter what. The whole unit could be sealed in that case -- no shaft seals that have to hold off steam pressure if the generator is inside the casing for example, direct coupled. No need for speed control (other than safety) if the generator is going to charge batteries -- it will be DC anyway (or alternator plus diodes).

Have you seen the old B&W books called "Steam, it's generation and use"? Boy are those thorough -- I have a couple I got in used bookstores from before McDermott bought them out. They have more info on water in all possible states than you'd think existed. I note that just this AM, McDermott spun off B&W again -- and their stock tanked 48% on open. B&W fell on hard times around asbestos issues and almost failed, McD saved them....but didn't know what they had -- B&W are THE guys in USA who do nuclear for example, having bought nearly all the competition earlier on.

The B&W guys are really good at what they do -- should a fusor get near to gain, they are who I'd be on the phone with right away.

The sound of those hit and miss engines is just so neat....they are a big attraction at the flea market in Hillsville (this is two-three blocks wide by a few miles long, and you cannot see it all in a day).

Turbines can do better than pistons -- these days they are pushing the high 40% range from calculated BTU in coal to output electricity -- but might be past our speed to make at that level (many stages with interstage reheats, first stage supercritical). However, a 2 stage design with the first stage pelton-wheel like, and the second (and any further stages) your basic turbo fan is fairly decent, and by controlling how many nozzles are open can handle a wide range of inputs -- I'd been looking at that too. As in, could one design a turbine with blades cast from melted down beer cans? Yes, these would wear out all too quick, but -- considering where they'd be going, maybe not a problem if the basic design makes it easy to keep up. A lot of people in some places have plenty of time, but not a lot of good toolage, and I've seen quite a lot of ingenuity from there, from cars made almost all out of scrap metal to even transformers made of cut up sheet metal for the cores (from back when beer cans were iron). If you can make them a design where the only parts that wear out can be made by them -- that's gold for all concerned.

No question IC engines are better -- but this is because they use a better fuel too, can't burn logs or coal in one. My purpose built backup generator for the solar system is sweet on that level. It uses a 6.5 hp high compression Honda engine driving the generator from a WWII Spitfire. After many thousands of hours, the generator brushes still look new -- I couldn't believe it when I tore it down "just in case" -- we must have really wanted to win that war. But also, the IC engines fail easier....and need two special fluids to work, not junk you just find laying around.

In my case, BTU's are nearly free anyway -- we have a large woodlot and a few tons of "thermal security" in the form of coal out back. Not to mention plenty of sun much of the time. But can't use any of those in an IC engine, hence the interest in something else. Particularly, things that work in sun-free February. Electricity from an IC engine is a buck a kwh when you consider wear along with oil and fuel.

What I was looking at was for power generation, simple and cheap, for myself and for parts of the world that need this kind of thing -- cheaper than my solar stuff, and possible for an idiot to run and repair. Safety in the event of a little over-firing would be a pretty big deal, which is why I mentioned that, along with self starting (for solar dynamic heat input). Can't count on a microprocessor control for 3rd world kinds of apps. This actually makes the turbine look best, if relief valves control the extra input nozzles to keep boiler pressure in range no matter what. The whole unit could be sealed in that case -- no shaft seals that have to hold off steam pressure if the generator is inside the casing for example, direct coupled. No need for speed control (other than safety) if the generator is going to charge batteries -- it will be DC anyway (or alternator plus diodes).

Have you seen the old B&W books called "Steam, it's generation and use"? Boy are those thorough -- I have a couple I got in used bookstores from before McDermott bought them out. They have more info on water in all possible states than you'd think existed. I note that just this AM, McDermott spun off B&W again -- and their stock tanked 48% on open. B&W fell on hard times around asbestos issues and almost failed, McD saved them....but didn't know what they had -- B&W are THE guys in USA who do nuclear for example, having bought nearly all the competition earlier on.

The B&W guys are really good at what they do -- should a fusor get near to gain, they are who I'd be on the phone with right away.

Posting as just me, not as the forum owner. Everything I say is "in my opinion" and YMMV -- which should go for everyone without saying.

-

Doug Coulter - Posts: 3515

- Joined: Wed Jul 14, 2010 7:05 pm

- Location: Floyd county, VA, USA

Re: Oregon Steam Up

I think the life span of a turbine made from pop cans would be measured in nanoseconds. POOF!

I suppose there is the sterling cycle. Not really practical I think. I believe there were some pretty decent sized engines made that ran and they seem to be a project that a lot of people enjoy building. There was even a CPU fan prototype that used a sterling engine to run its fan.

You can use coal and wood to run a IC engine. You turn it into producer gas and it will run IC engines. During WWII many vehicles were converted to run on this. Basically its carbon monoxide.

I suppose there is the sterling cycle. Not really practical I think. I believe there were some pretty decent sized engines made that ran and they seem to be a project that a lot of people enjoy building. There was even a CPU fan prototype that used a sterling engine to run its fan.

You can use coal and wood to run a IC engine. You turn it into producer gas and it will run IC engines. During WWII many vehicles were converted to run on this. Basically its carbon monoxide.

- Jerry

- Posts: 573

- Joined: Sun Jul 18, 2010 12:07 am

- Location: Beaverton, OR

Re: Oregon Steam Up

Oh, I wasn't thinking of making the whole thing of Al, just the blades -- you give them a sample(s) they can use for sandcasting to replace them.

From what I hear, it almost doesn't matter what you make turbine blades of -- even tungsten carbide erodes fairly quick at high loadings, and sometimes

softer stuff works better if it's tough material. (at these low temps, the rules are way different for gas turbines, jets and such)

You make the rest out of good stuff, and it will last "forever" without the steam erosion. Think some fairly slow speed, like 3000 rpm or

maybe twice that. If you look into turbine designs, there's a fancy shape on the bottom of the blades that locks them into the rotor proper,

to make them real easy to replace (looks like an upside down christmas tree sort of). The blades are only about the last inch of the diameter,

the rest is just a big metal disk. I *used* to have a good book on steam turbine design, but it went back to its owner awhile back, so I'm going from memory here.

At any rate, it said that a first pelton type stage driven by one or more nozzles, followed by a stage that looks more like what most

imagine for a turbine (little airplane wings) with stator between the stages gets you a big part of the way there -- adding 11-12 more

stages as in a power plant is diminishing returns very quicklike.

Yeah, you can gasify things, you usually get a mix, but that takes/wastes a lot of energy and work -- and it stinks. You get methane, CO2 and other

stuff (depends on if you add water to the process). And tars -- which will ruin most things, except they burn just fine in a steam boiler with no

other work -- even dung works, or dry grass. I'm thinking 3rd world, and the village idiot running it on a day to day basis. The village tinker fixes it from time to time,

that sort of thing. In my own case, I do both....but the design would have to have real low initial costs -- a gasification plant is a doubling at least there.

Yeah, all the stirling things I've seen run far too slow to be useful here, and I was never in love with the idea. It's more fun for a slow almost no power thing

to make the old deal with a bicycle wheel and rubber bands that runs with the bottom wet in water, and uses the thermal contraction of rubber, with an offset hub, to

run of the temperature differential between wet and dry rubber bands....cool, but not real useful. That was an old amateur scientist thing from SciAm.

Kind of like the drinking bird idea - almost no power but looks like "perpetual motion" while running.

From what I hear, it almost doesn't matter what you make turbine blades of -- even tungsten carbide erodes fairly quick at high loadings, and sometimes

softer stuff works better if it's tough material. (at these low temps, the rules are way different for gas turbines, jets and such)

You make the rest out of good stuff, and it will last "forever" without the steam erosion. Think some fairly slow speed, like 3000 rpm or

maybe twice that. If you look into turbine designs, there's a fancy shape on the bottom of the blades that locks them into the rotor proper,

to make them real easy to replace (looks like an upside down christmas tree sort of). The blades are only about the last inch of the diameter,

the rest is just a big metal disk. I *used* to have a good book on steam turbine design, but it went back to its owner awhile back, so I'm going from memory here.

At any rate, it said that a first pelton type stage driven by one or more nozzles, followed by a stage that looks more like what most

imagine for a turbine (little airplane wings) with stator between the stages gets you a big part of the way there -- adding 11-12 more

stages as in a power plant is diminishing returns very quicklike.

Yeah, you can gasify things, you usually get a mix, but that takes/wastes a lot of energy and work -- and it stinks. You get methane, CO2 and other

stuff (depends on if you add water to the process). And tars -- which will ruin most things, except they burn just fine in a steam boiler with no

other work -- even dung works, or dry grass. I'm thinking 3rd world, and the village idiot running it on a day to day basis. The village tinker fixes it from time to time,

that sort of thing. In my own case, I do both....but the design would have to have real low initial costs -- a gasification plant is a doubling at least there.

Yeah, all the stirling things I've seen run far too slow to be useful here, and I was never in love with the idea. It's more fun for a slow almost no power thing

to make the old deal with a bicycle wheel and rubber bands that runs with the bottom wet in water, and uses the thermal contraction of rubber, with an offset hub, to

run of the temperature differential between wet and dry rubber bands....cool, but not real useful. That was an old amateur scientist thing from SciAm.

Kind of like the drinking bird idea - almost no power but looks like "perpetual motion" while running.

Posting as just me, not as the forum owner. Everything I say is "in my opinion" and YMMV -- which should go for everyone without saying.

-

Doug Coulter - Posts: 3515

- Joined: Wed Jul 14, 2010 7:05 pm

- Location: Floyd county, VA, USA

Re: Oregon Steam Up

Jerry, Hi. I like your posts about old machinery. We occasionally have old engine shows around here and they are fun to go to. Here is an engine I saw the other day at the gold mining area I went to. At first I thought it was a hit and miss, but the owner told me it was an Indian knock off of an early American diesel engine. This one was "new" and he wanted about $1300 for it. It has a life of 100k hours. They aren't importing anymore because they don't quite meet EPA standards. -bill

-

Bill Fain - Posts: 90

- Joined: Sat Jul 17, 2010 10:23 am

Re: Oregon Steam Up

Bill, the original engines were called Lister engines and the knock-offs are commonly called "Listeroids". They're slow running diesels that seem to last forever... and then some.

-

Joe Jarski - Posts: 231

- Joined: Thu Sep 16, 2010 8:37 pm

- Location: SouthEast Michigan

Re: Oregon Steam Up

They are actually knock offs of the old English Lister diesels. They call these indian ones "Listeroids".

They will run on almost anything.

They will run on almost anything.

- Jerry

- Posts: 573

- Joined: Sun Jul 18, 2010 12:07 am

- Location: Beaverton, OR

Re: Oregon Steam Up

Hi, Thanks for the info Joe and Jerry. I do remember he said it would run on about anything. Might be pretty useful if this economic situation continues to go south. Roughly how many BHP? You say slow; 500-1000 RPM? Another guy told me about a military generator he bought with I believe a "Teledyne" engine. He said it was designed to run off almost anything as well. -bill

-

Bill Fain - Posts: 90

- Joined: Sat Jul 17, 2010 10:23 am

25 posts

• Page 1 of 3 • 1, 2, 3

Return to The water cooler -- disscusions about anything

Who is online

Users browsing this forum: No registered users and 7 guests