Got the EDX running, EDX allows you to do elemental analysis by sampling the x-rays that are created when the electron beam hits the target in the microscope.

I picked up a 50L dewar of liquid nitrogen Monday and filled the dewar on the EDX head. You need to let it sit from 4-10 hours to make sure the sensor is cooled. If the sensor is not cool (cryogenic temps) the sensor will be ruined.

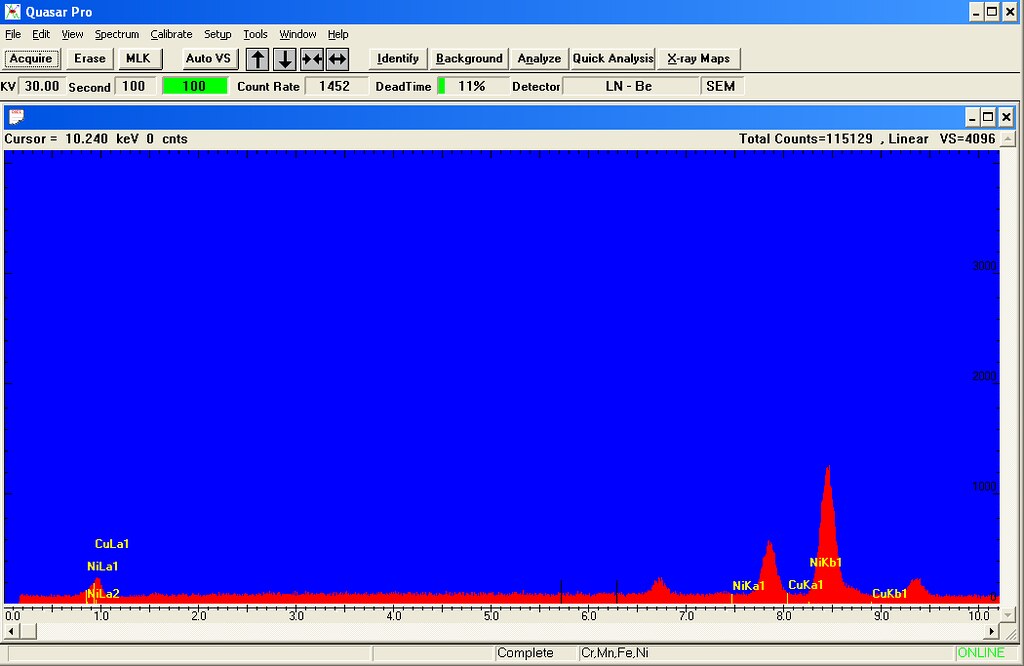

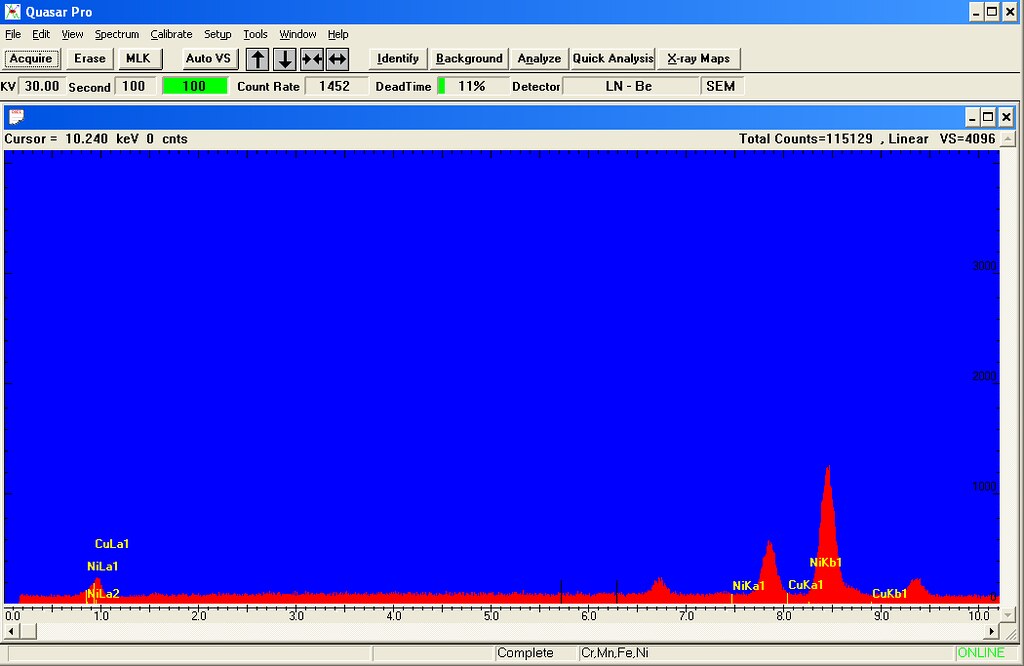

I threw a dime in the chamber and scanned it and did an acquisition with the software and it showed me some peaks, a dime's outer plating is about 75% copper and 25% nickel. The histogram showed some peaks pretty close to where they should be, it needs to be calibrated and the gains adjusted but it is pretty good for just hooking it up. I need to go through the manual some more and do all the adjustments.

I also picked up another sensor head off ebay the other day. It has different windows you can use as well as a windowless operation mode that will allow you to sample light elements like carbon and oxygen. The standard sensor used a beryllium window which makes it hard to see light elements.

dimeedx

dimeedx by

macona, on Flickr

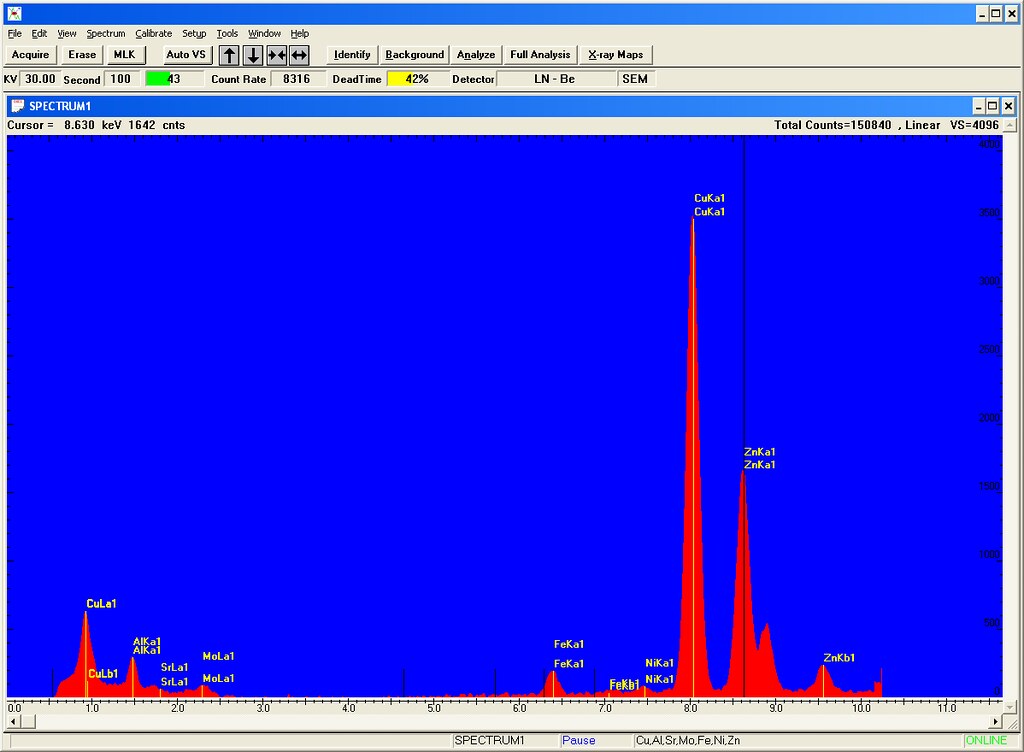

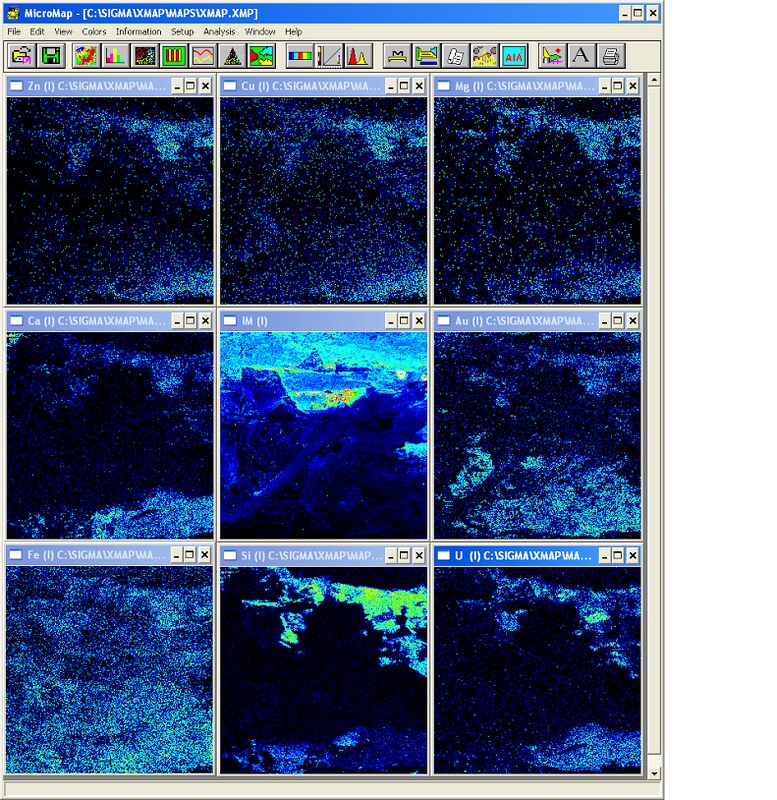

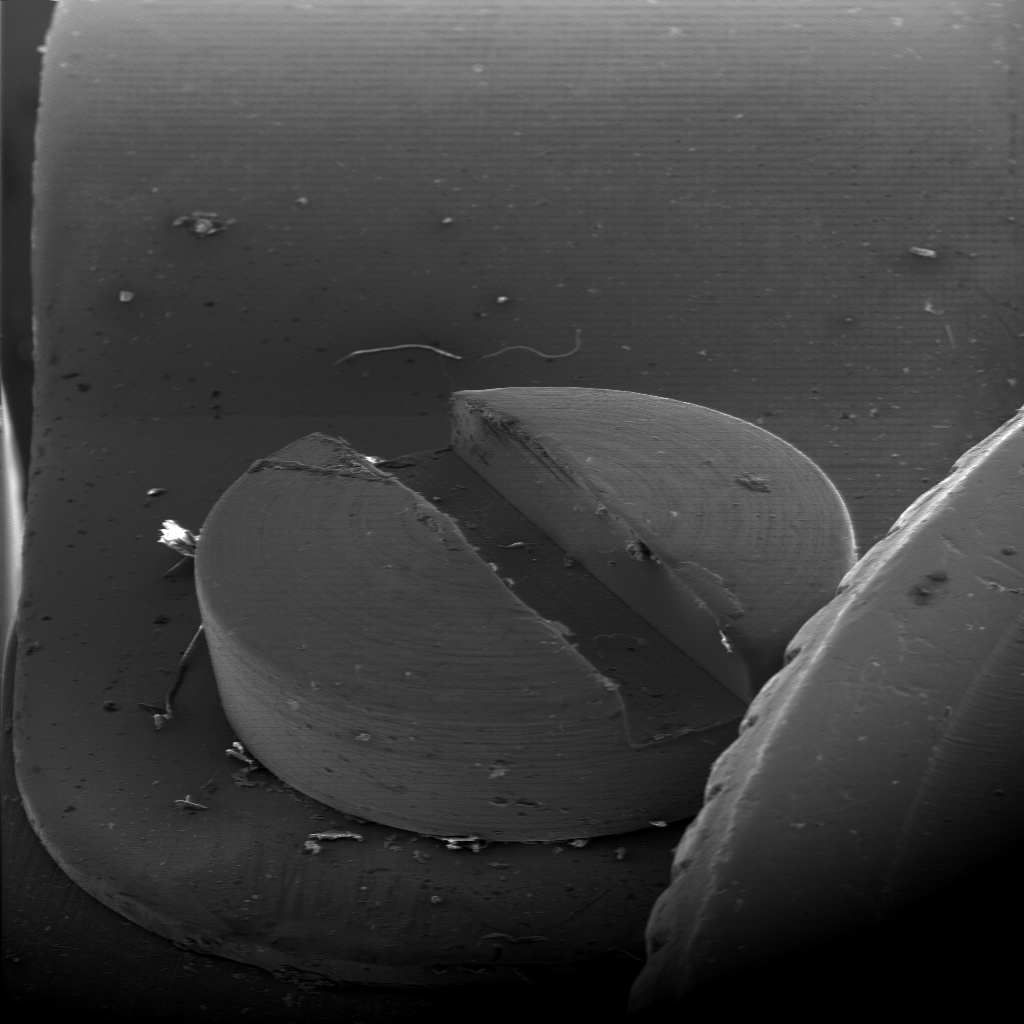

SCREW by macona, on Flickr

SCREW by macona, on Flickr