http://www.cnczone.com/forums/vertical_ ... grade.html

Its been a good mill. A few little quirks. If you powered up the servos with the drives enabled it would jump and sometimes fault out or trip one of the breakers inside of the control for the drives. This was caused by the Pixie step/direction to analog control boards. These boards would take step and direction inputs and control standard analog servo drives with encoder feedback. They worked pretty well, but tuning was a nightmare. Not only did you have to tuned the analog drives, you also had to tune the position loop. It had some decent gui software but I really never got it tuned like it should. I would get random follow error trips when the machine changed direction.

Rather annoying. That and the X axis motor is rather long and I dont know how many time I have ran into it.

With this last week being a production break from Paranorman I figured I would finally have some time to do something about these problems. A couple years ago I got that Mitsubishi injection molder. Among the servos on it were two Mitsubishi MR-H series 1kw servo drives and motors. I also had another Mitsubishi 1.5kw MR-J series drive and motor from back when I was gearing up to do the servo retrofit on my 10EE. The 1kw motors were much smaller than the old ones and about 5" square. The 1.5 is a touch bigger than the old motor. Both models of drives have step and direction input native.

In anticipation of doing this project I had machined adapter plates and motor mounts for the motors ahead of time. I also hand some small circuit boards made up through the dorkbotpdx circuit board service. These boards broke out the 40 pin MDR connector to give me easy access to the step, direction, and alarm out lines.

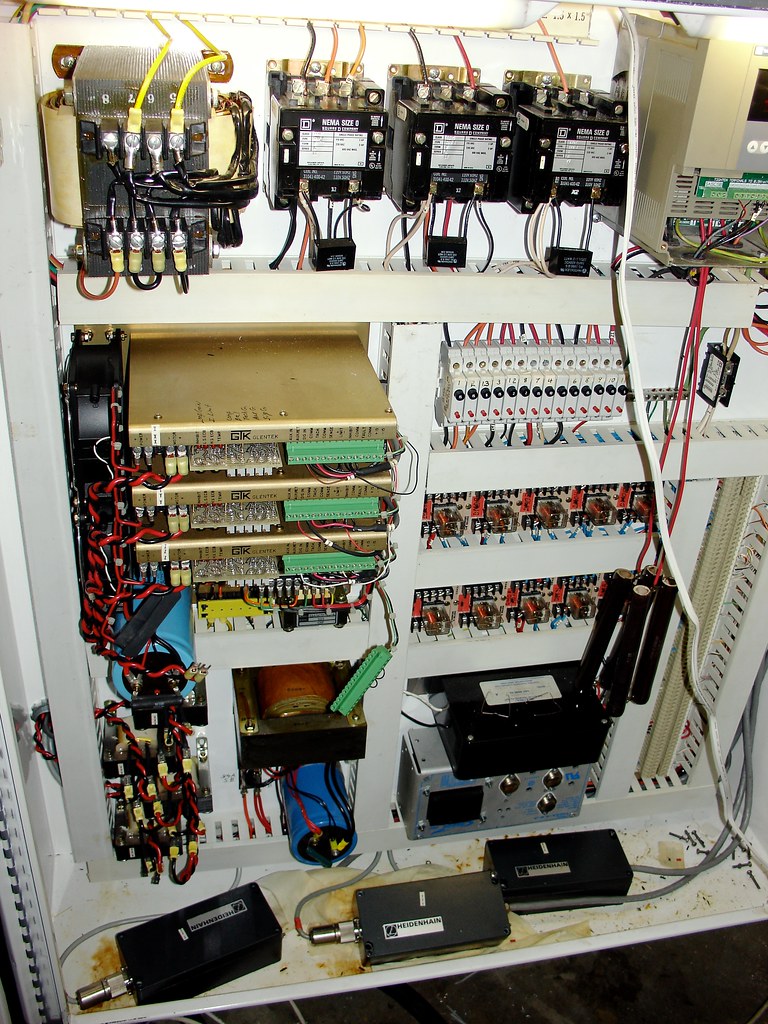

This is what it looked like after the first retrofit. The gold parts in the control box are the servo drives, the main power transformer up top, aux transformer below that ran the old control, chokes below the drives. Also three contactors that controlled coolant, servo power, and a spare. The three Heidenhain boxes on the bottom are interpolators for the linear scales it had mounted for feedback on the original control. I initially tried to used the scaler but the performance was terrible.

DSC03386.JPG by macona, on Flickr

DSC02756.JPG by macona, on Flickr

DSC02758.JPG by macona, on Flickr