by Doug Coulter » Mon Sep 20, 2010 10:56 pm

by Doug Coulter » Mon Sep 20, 2010 10:56 pm

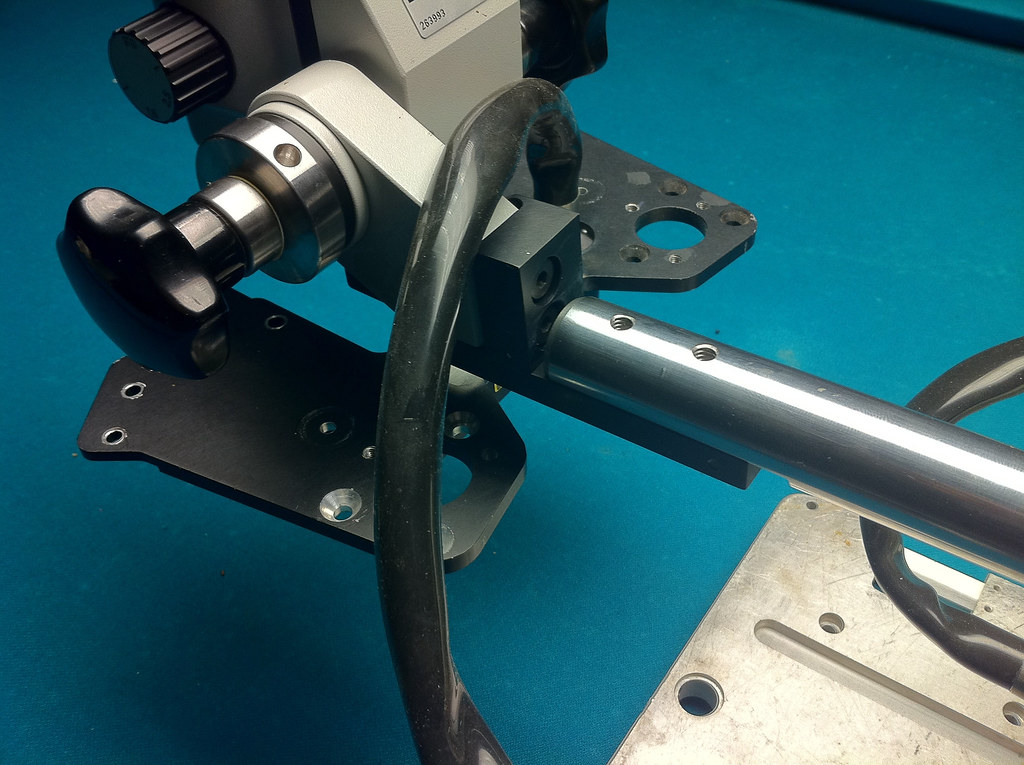

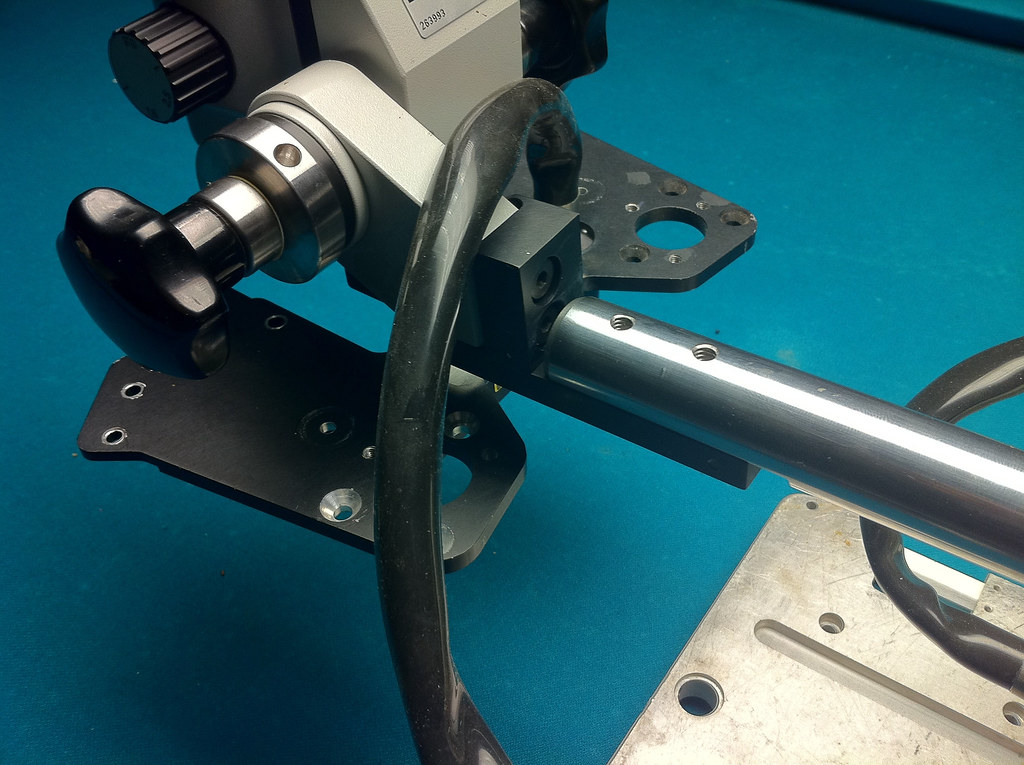

I've got two really decent stereo mics with long working range, and one of them has eyepieces I can put in to get to about 90x with that long range. Like finally having compressed air at all the workstations, I no longer understand how I ever got along without them. Nice work! That's a real force multiplier.

The older I get, the more often I reach for anything optical to help me, from 1.5 diopter reading glasses to the 5x headband to the microscopes. Boy do they ever help.

And stereo is just so important in real life I don't understand how people get along without that. And bright lights. I use a 20w halogen desk lamp at those stations, and have UV available too.

Oh, as a machinist, I'm sure you've gotten the odd bit of metal in your skin. I use my main scope to find those and get them out, stat! Way worth it in the damage to cure ratio.

I have found some real special tweezers for this and smd work, I'll put up a link the next time I find them for sale surplus -- they actually reliably meet at the tiny tips (about 20 mils wide behind the pin-sharp points). Just so much better than the usual run of them that it's like that first mill after using an eggbeater drill. Little things matter sometimes.

Posting as just me, not as the forum owner. Everything I say is "in my opinion" and YMMV -- which should go for everyone without saying.