Pirani gauge:

Coulter's Smithing Home.

This was originally inspired by this link:

Thermister vacuum gauge

which gives some good information about how to do things like this

and what to expect. Go ahead, read it, we will wait. There's

information there that won't be duplicated here. Thanks are due

to our forthcoming Canadian friend, who must be a kindred spirit.

Without thinking it through, Doug ordered a thermistor

and balancing resistor from DigiKey to try this one; we had the rest

of the components in stock. Well...Doug didn't figure on the thermal

conductivity of the thermister leads as a factor, which is in fact

huge and the main factor involved, so the first attempt

didn't work out too well. We will try again with a better part for

this job, or simply better mounting on thin wires. Of course, that

won't really work out with this heavy (about a 1/4 watt resistor) part.

It would sag and contact the vessel, so would not be floating thermally.

However, one who won't be stopped can't be stopped, so, realizing that

the early gauges were made with tungsten as the heater and sensing element,

the pilot lamp drawer was gone through to find a suitable bulb.

The current

pick is a bi–pin 14v 50 mA bulb because we happened to have a bunch of

them in stock, and the speeds and feeds are about right. Here's a picture

of one. The number is PL10160 if that helps anybody.

This bulb was used for the flashing lights in the mainframes Doug maintained

in the 70's, so there were a few laying around. It has 27 ohms cold

resistance. To modify this for gauge use, a hole is made in the top

on the belt sander. Just be gentle. The bulb is a vacuum one to

start with, so on breakthrough it will suck in air, dirt, and so

on. Most of this will shake back out if the filament survives. The bulb

is precisely .200 inch OD, so you can slip it into that size hole in

some plumbing and the base will not pass the hole. Then you can apply

your sealant of choice.

The current

pick is a bi–pin 14v 50 mA bulb because we happened to have a bunch of

them in stock, and the speeds and feeds are about right. Here's a picture

of one. The number is PL10160 if that helps anybody.

This bulb was used for the flashing lights in the mainframes Doug maintained

in the 70's, so there were a few laying around. It has 27 ohms cold

resistance. To modify this for gauge use, a hole is made in the top

on the belt sander. Just be gentle. The bulb is a vacuum one to

start with, so on breakthrough it will suck in air, dirt, and so

on. Most of this will shake back out if the filament survives. The bulb

is precisely .200 inch OD, so you can slip it into that size hole in

some plumbing and the base will not pass the hole. Then you can apply

your sealant of choice.

|

Here is the gauge plumbed into the real vacuum system. It is epoxied

into the pipe cap, which is in turn glued on with a 50:50 mixture

of beeswax and rosin. Both of those can be had at McMaster–Carr.

The red stuff is Glyptal lacquer, available at Caswell Plating. The above

compounds are really useful in medium vacuum work. The former melts for

easy removal, while the Glyptal polymerizes upon baking to be a very low

vapor pressure leak filler. Here we just used it to see if there was

a leak at all – if there was, the gauge tells you quick when

the leak is covered in Glyptal, and the usual procedure from there is

to really fix the leak with solder or something like that.

To make the beeswax and rosin mixture, you will initially

have to heat it above 100 C, using maybe an oil bath and melting equal

weights of the components in a little jar. I used a pyrex beaker and

an alcohol lamp here. Once it has been made, it

doesn't have to get as hot to remelt, it takes lots of heat that first time

just to get the rosin to dissolve in the wax. After that, you can use

boiling water to remelt it. I'm sure the ultra high vacuum guys are

squirming at this point, but the truth is, this stuff is a lot lower

vapor pressure than say, rust, cat hair, fingerprints, and all the other

stuff an amateur gets into a vacuum system. It's never been an issue here,

as we're not even trying to go to 10-9

mm of Hg or below. We just want to do metal vapor deposition and play

some games with protons.

Here is the gauge plumbed into the real vacuum system. It is epoxied

into the pipe cap, which is in turn glued on with a 50:50 mixture

of beeswax and rosin. Both of those can be had at McMaster–Carr.

The red stuff is Glyptal lacquer, available at Caswell Plating. The above

compounds are really useful in medium vacuum work. The former melts for

easy removal, while the Glyptal polymerizes upon baking to be a very low

vapor pressure leak filler. Here we just used it to see if there was

a leak at all – if there was, the gauge tells you quick when

the leak is covered in Glyptal, and the usual procedure from there is

to really fix the leak with solder or something like that.

To make the beeswax and rosin mixture, you will initially

have to heat it above 100 C, using maybe an oil bath and melting equal

weights of the components in a little jar. I used a pyrex beaker and

an alcohol lamp here. Once it has been made, it

doesn't have to get as hot to remelt, it takes lots of heat that first time

just to get the rosin to dissolve in the wax. After that, you can use

boiling water to remelt it. I'm sure the ultra high vacuum guys are

squirming at this point, but the truth is, this stuff is a lot lower

vapor pressure than say, rust, cat hair, fingerprints, and all the other

stuff an amateur gets into a vacuum system. It's never been an issue here,

as we're not even trying to go to 10-9

mm of Hg or below. We just want to do metal vapor deposition and play

some games with protons.

|

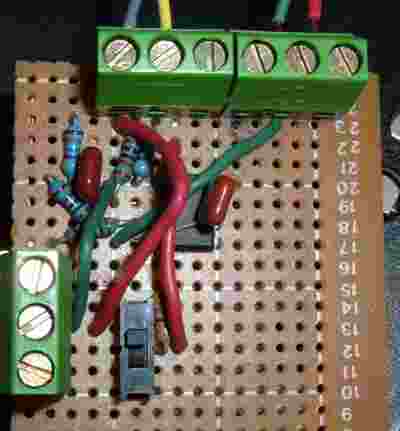

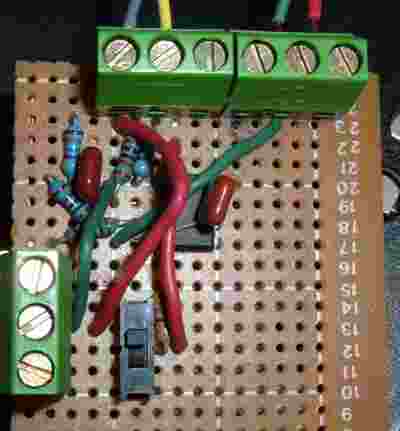

Here are the electronics. As you can see, this was whomped up in

no time on a piece of not very good perfboard. The opamp used was

a TLV 4112, which is a 5v high current opamp, so no output follower

for current boosting was needed. The switch was a mistake. At one

point the system was pumping down so low that Doug thought we needed

and could get more range by trying a higher value balancing resistor

and heating the element more to make things more sensitive. Well, at

any sort of incandescence, the tungsten filament dies very fast if there

is any air or water vapor present. They will be in most medium vacuum

systems. Note that 1% metal film resistors are used throughout. Not

sure if this matters, they just happened to be in stock, so why not?

There is a second section available in the opamp and on the terminal

strips, as the final vacuum system will need at least two of these.

We definitely have an urge to lay out a PCB for this design, once finalized

and sell the result to other amateurs. It just offends us that you'd

otherwise have to pay on the order of a grand for this sort of thing,

even used. Look how simple it is! OK, for the big bucks you get a nice

vacuum flange that you have to mate on your system at your cost...gee.

Here are the electronics. As you can see, this was whomped up in

no time on a piece of not very good perfboard. The opamp used was

a TLV 4112, which is a 5v high current opamp, so no output follower

for current boosting was needed. The switch was a mistake. At one

point the system was pumping down so low that Doug thought we needed

and could get more range by trying a higher value balancing resistor

and heating the element more to make things more sensitive. Well, at

any sort of incandescence, the tungsten filament dies very fast if there

is any air or water vapor present. They will be in most medium vacuum

systems. Note that 1% metal film resistors are used throughout. Not

sure if this matters, they just happened to be in stock, so why not?

There is a second section available in the opamp and on the terminal

strips, as the final vacuum system will need at least two of these.

We definitely have an urge to lay out a PCB for this design, once finalized

and sell the result to other amateurs. It just offends us that you'd

otherwise have to pay on the order of a grand for this sort of thing,

even used. Look how simple it is! OK, for the big bucks you get a nice

vacuum flange that you have to mate on your system at your cost...gee.

|

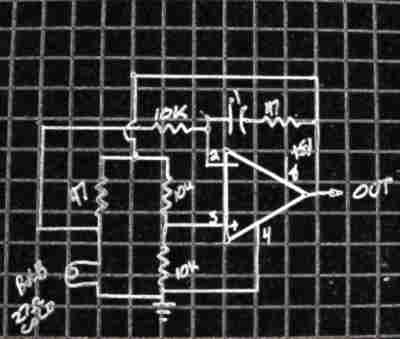

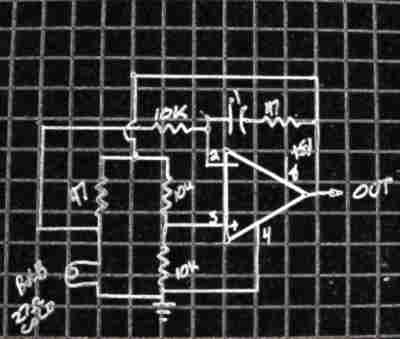

Here is the very simple schematic. We used the TLV-4112 as we had

them in stock, and they have plenty of current output available to

drive a small lamp such as this without help. Simple is good. You

should, of course, bypass the 5v power on board. We use a little supply

that puts out 5v and ±12v to support the vacuum system in

general. This is just a small switcher we bought and put into a

plastic box with binding posts. Total cost was under $20 compared

to the normal cost for a bench supply. It was fun processing this

image in the Gimp to make it readable. It sure is hard to take a good

picture of a pencil drawing on graph paper. Next time I will skip

the graph paper. Stuck with the pencil as that's what fits through

the stencils. Yeah, I should get a schematic capture program.

On the other hand, that whole production, including the drawing

took under 5 minutes. "Too fussy wastes manhours."

Here is the very simple schematic. We used the TLV-4112 as we had

them in stock, and they have plenty of current output available to

drive a small lamp such as this without help. Simple is good. You

should, of course, bypass the 5v power on board. We use a little supply

that puts out 5v and ±12v to support the vacuum system in

general. This is just a small switcher we bought and put into a

plastic box with binding posts. Total cost was under $20 compared

to the normal cost for a bench supply. It was fun processing this

image in the Gimp to make it readable. It sure is hard to take a good

picture of a pencil drawing on graph paper. Next time I will skip

the graph paper. Stuck with the pencil as that's what fits through

the stencils. Yeah, I should get a schematic capture program.

On the other hand, that whole production, including the drawing

took under 5 minutes. "Too fussy wastes manhours."

|

Any digital or analog meter can be used to read this gauge. You can

sort of calibrate it via looking at where the knees are on the curves

given for the thermocouple gauge in the link above, with a little mental

interpolation. This is a relative gauge at any rate. Ours reads a little

over 3.5v at atmospheric, and got down to about .55v at one point with

a tight door gasket on the system. The bulb is running at

1/2 of these voltages to reach a particular constant temperature of

a couple hundred °C where the tungsten filament has a resistance of 47 ohms.

As tungsten has a positive coefficient of resistance, the

bridge connections were reversed, and a 47 ohm balancing resistor was

used. The idea here is to force the tungsten element to about double its

resistance due to heating, but not heat it up too far. Tungsten and air

get along a bit too well at high temperatures. An improvement on this

design would include using fatter tungsten wire for the element. Experiments

are underway to find a good one that is gettable by everyone, and to find

out if maybe with the lower resistance a 4 wire connection to it will be

needed. We are also considering trying a model engine glow plug. These

are (were?) made with platinum wire as the element. It doesn't have

quite the thermal coefficient that tungsten does, but it doesn't take

much to make this circuit work with the full gain of the opamp available.

Stay tuned. We really want to make something here we can sell in bulk,

that is cheap and easy to apply. The glow plug, if it works, would have

some advantages, as it already has threads and is fairly airtight.

Update: I went to Central Hobbies and got one each of every type glow

plug they sell. I ran current/voltage curves on some of them, and found

out that they have enough temperature coefficient to work, but have

very low base resistance, and may consume too much power or make

too much heat. A real test is obviously in order. At this time, the

cheaper Fox plugs seem best for this. Based on the curves, I would set

these to run at about 0.7v and 1.7 amp at room temperature and atmosphere.

That's going to take a pretty hefty output stage to drive, and there

will likely be problems if the connections aren't really good, but it

still seems worth pursuing. For one thing, the filament is red at this

operating point, but will go all day without failure in STP conditions,

where a tungsten filament would last only a couple of seconds. The high

temperature operating point is good as then enviornmental temperature

affects the reading a lot less. Ten degrees is just a lot smaller

fraction of 900 than it is of 100, whether °C or °F. I have no

clue whether the action of hot platinum on residual gasses will be

a positive or negative thing. One thing for sure, the mount for the

glow plug will need a heat sink if it is going to be affixed to the

system with beeswax–rosin mixture.

Coulter's Smithing Home

Here's how to contact us:

Contact information

The current

pick is a bi–pin 14v 50 mA bulb because we happened to have a bunch of

them in stock, and the speeds and feeds are about right. Here's a picture

of one. The number is PL10160 if that helps anybody.

This bulb was used for the flashing lights in the mainframes Doug maintained

in the 70's, so there were a few laying around. It has 27 ohms cold

resistance. To modify this for gauge use, a hole is made in the top

on the belt sander. Just be gentle. The bulb is a vacuum one to

start with, so on breakthrough it will suck in air, dirt, and so

on. Most of this will shake back out if the filament survives. The bulb

is precisely .200 inch OD, so you can slip it into that size hole in

some plumbing and the base will not pass the hole. Then you can apply

your sealant of choice.

The current

pick is a bi–pin 14v 50 mA bulb because we happened to have a bunch of

them in stock, and the speeds and feeds are about right. Here's a picture

of one. The number is PL10160 if that helps anybody.

This bulb was used for the flashing lights in the mainframes Doug maintained

in the 70's, so there were a few laying around. It has 27 ohms cold

resistance. To modify this for gauge use, a hole is made in the top

on the belt sander. Just be gentle. The bulb is a vacuum one to

start with, so on breakthrough it will suck in air, dirt, and so

on. Most of this will shake back out if the filament survives. The bulb

is precisely .200 inch OD, so you can slip it into that size hole in

some plumbing and the base will not pass the hole. Then you can apply

your sealant of choice.

Here is the gauge plumbed into the real vacuum system. It is epoxied

into the pipe cap, which is in turn glued on with a 50:50 mixture

of beeswax and rosin. Both of those can be had at McMaster–Carr.

The red stuff is Glyptal lacquer, available at Caswell Plating. The above

compounds are really useful in medium vacuum work. The former melts for

easy removal, while the Glyptal polymerizes upon baking to be a very low

vapor pressure leak filler. Here we just used it to see if there was

a leak at all – if there was, the gauge tells you quick when

the leak is covered in Glyptal, and the usual procedure from there is

to really fix the leak with solder or something like that.

To make the beeswax and rosin mixture, you will initially

have to heat it above 100 C, using maybe an oil bath and melting equal

weights of the components in a little jar. I used a pyrex beaker and

an alcohol lamp here. Once it has been made, it

doesn't have to get as hot to remelt, it takes lots of heat that first time

just to get the rosin to dissolve in the wax. After that, you can use

boiling water to remelt it. I'm sure the ultra high vacuum guys are

squirming at this point, but the truth is, this stuff is a lot lower

vapor pressure than say, rust, cat hair, fingerprints, and all the other

stuff an amateur gets into a vacuum system. It's never been an issue here,

as we're not even trying to go to 10-9

mm of Hg or below. We just want to do metal vapor deposition and play

some games with protons.

Here is the gauge plumbed into the real vacuum system. It is epoxied

into the pipe cap, which is in turn glued on with a 50:50 mixture

of beeswax and rosin. Both of those can be had at McMaster–Carr.

The red stuff is Glyptal lacquer, available at Caswell Plating. The above

compounds are really useful in medium vacuum work. The former melts for

easy removal, while the Glyptal polymerizes upon baking to be a very low

vapor pressure leak filler. Here we just used it to see if there was

a leak at all – if there was, the gauge tells you quick when

the leak is covered in Glyptal, and the usual procedure from there is

to really fix the leak with solder or something like that.

To make the beeswax and rosin mixture, you will initially

have to heat it above 100 C, using maybe an oil bath and melting equal

weights of the components in a little jar. I used a pyrex beaker and

an alcohol lamp here. Once it has been made, it

doesn't have to get as hot to remelt, it takes lots of heat that first time

just to get the rosin to dissolve in the wax. After that, you can use

boiling water to remelt it. I'm sure the ultra high vacuum guys are

squirming at this point, but the truth is, this stuff is a lot lower

vapor pressure than say, rust, cat hair, fingerprints, and all the other

stuff an amateur gets into a vacuum system. It's never been an issue here,

as we're not even trying to go to 10-9

mm of Hg or below. We just want to do metal vapor deposition and play

some games with protons.

Here are the electronics. As you can see, this was whomped up in

no time on a piece of not very good perfboard. The opamp used was

a TLV 4112, which is a 5v high current opamp, so no output follower

for current boosting was needed. The switch was a mistake. At one

point the system was pumping down so low that Doug thought we needed

and could get more range by trying a higher value balancing resistor

and heating the element more to make things more sensitive. Well, at

any sort of incandescence, the tungsten filament dies very fast if there

is any air or water vapor present. They will be in most medium vacuum

systems. Note that 1% metal film resistors are used throughout. Not

sure if this matters, they just happened to be in stock, so why not?

There is a second section available in the opamp and on the terminal

strips, as the final vacuum system will need at least two of these.

We definitely have an urge to lay out a PCB for this design, once finalized

and sell the result to other amateurs. It just offends us that you'd

otherwise have to pay on the order of a grand for this sort of thing,

even used. Look how simple it is! OK, for the big bucks you get a nice

vacuum flange that you have to mate on your system at your cost...gee.

Here are the electronics. As you can see, this was whomped up in

no time on a piece of not very good perfboard. The opamp used was

a TLV 4112, which is a 5v high current opamp, so no output follower

for current boosting was needed. The switch was a mistake. At one

point the system was pumping down so low that Doug thought we needed

and could get more range by trying a higher value balancing resistor

and heating the element more to make things more sensitive. Well, at

any sort of incandescence, the tungsten filament dies very fast if there

is any air or water vapor present. They will be in most medium vacuum

systems. Note that 1% metal film resistors are used throughout. Not

sure if this matters, they just happened to be in stock, so why not?

There is a second section available in the opamp and on the terminal

strips, as the final vacuum system will need at least two of these.

We definitely have an urge to lay out a PCB for this design, once finalized

and sell the result to other amateurs. It just offends us that you'd

otherwise have to pay on the order of a grand for this sort of thing,

even used. Look how simple it is! OK, for the big bucks you get a nice

vacuum flange that you have to mate on your system at your cost...gee.

Here is the very simple schematic. We used the TLV-4112 as we had

them in stock, and they have plenty of current output available to

drive a small lamp such as this without help. Simple is good. You

should, of course, bypass the 5v power on board. We use a little supply

that puts out 5v and ±12v to support the vacuum system in

general. This is just a small switcher we bought and put into a

plastic box with binding posts. Total cost was under $20 compared

to the normal cost for a bench supply. It was fun processing this

image in the Gimp to make it readable. It sure is hard to take a good

picture of a pencil drawing on graph paper. Next time I will skip

the graph paper. Stuck with the pencil as that's what fits through

the stencils. Yeah, I should get a schematic capture program.

On the other hand, that whole production, including the drawing

took under 5 minutes. "Too fussy wastes manhours."

Here is the very simple schematic. We used the TLV-4112 as we had

them in stock, and they have plenty of current output available to

drive a small lamp such as this without help. Simple is good. You

should, of course, bypass the 5v power on board. We use a little supply

that puts out 5v and ±12v to support the vacuum system in

general. This is just a small switcher we bought and put into a

plastic box with binding posts. Total cost was under $20 compared

to the normal cost for a bench supply. It was fun processing this

image in the Gimp to make it readable. It sure is hard to take a good

picture of a pencil drawing on graph paper. Next time I will skip

the graph paper. Stuck with the pencil as that's what fits through

the stencils. Yeah, I should get a schematic capture program.

On the other hand, that whole production, including the drawing

took under 5 minutes. "Too fussy wastes manhours."