Nearly everyone knows what an assembled spark gap looks like, but just

in case, here it is ready to go. Pairs of nuts will adorn the ends and

clamp the wires between the main terminals, and the trigger will come

into the 10–32 screw on top. The trigger spark emits enough

ultra–violet light and probably a little ionized metal to start current

flowing through the main gap, which is set far enough apart to not trigger

without this stimulus. This might be very important for some of our

projects, as the little rail gun this will drive is used as a detonator

for explosives. The idea is to make something safer than mercury

fulminate or lead azide based detonators. Both of those are dangerous

AND poisonous, though we make those too. Our detonator design might

be called a "chip slapper". The idea is to have a short little

rail gun accellerate a small cloud of plasma to a high enough speed to

shock-initiate some HE, which in our case will be PETN. The plasma will

originate as a small piece of wire between the rails at the beginning of

the 1/4" long rails. I have tried 1 mil gold, tungsten, and other

things my sources say work, but frankly, a strand of the cheap speaker

wire that makes up the rails seems to work just as well. Probably because

I don't really need anywhere near this much energy to do the job. Well,

I have it, and reliability is a very good thing

around explosives! In this design, ensuring the capacitor isn't charged

is enough to guarantee no unintended firing, short of getting hit with

a bolt of lightning.

Nearly everyone knows what an assembled spark gap looks like, but just

in case, here it is ready to go. Pairs of nuts will adorn the ends and

clamp the wires between the main terminals, and the trigger will come

into the 10–32 screw on top. The trigger spark emits enough

ultra–violet light and probably a little ionized metal to start current

flowing through the main gap, which is set far enough apart to not trigger

without this stimulus. This might be very important for some of our

projects, as the little rail gun this will drive is used as a detonator

for explosives. The idea is to make something safer than mercury

fulminate or lead azide based detonators. Both of those are dangerous

AND poisonous, though we make those too. Our detonator design might

be called a "chip slapper". The idea is to have a short little

rail gun accellerate a small cloud of plasma to a high enough speed to

shock-initiate some HE, which in our case will be PETN. The plasma will

originate as a small piece of wire between the rails at the beginning of

the 1/4" long rails. I have tried 1 mil gold, tungsten, and other

things my sources say work, but frankly, a strand of the cheap speaker

wire that makes up the rails seems to work just as well. Probably because

I don't really need anywhere near this much energy to do the job. Well,

I have it, and reliability is a very good thing

around explosives! In this design, ensuring the capacitor isn't charged

is enough to guarantee no unintended firing, short of getting hit with

a bolt of lightning.

Here is the gap taken apart. For reasons that should be obvious, the

pipe is only glued to one of the caps. One big reason for doing this

in PVC pipe, other than that it's a good insulator and alignment jig, is

that the prototype gap was VERY noisy, comparable to a .38 pistol

shot in the room. Even with warning, everyone jumped (and there were

more–embarrassing mishaps). Since the planned application will only

need the gap to fire infrequently, there is no need for ventilation and

cooling, as there would be for instance with a gap used for a Tesla coil.

The expected failure mode for this gap will be pitting and evaporation

of the main electrodes onto the plastic, rendering it conductive.

Here is the gap taken apart. For reasons that should be obvious, the

pipe is only glued to one of the caps. One big reason for doing this

in PVC pipe, other than that it's a good insulator and alignment jig, is

that the prototype gap was VERY noisy, comparable to a .38 pistol

shot in the room. Even with warning, everyone jumped (and there were

more–embarrassing mishaps). Since the planned application will only

need the gap to fire infrequently, there is no need for ventilation and

cooling, as there would be for instance with a gap used for a Tesla coil.

The expected failure mode for this gap will be pitting and evaporation

of the main electrodes onto the plastic, rendering it conductive.

Here are the separate pieces. As contact evaporation was a big concern

based on work with a prototype, the gap faces here were plated, first

with copper, and then with chromium, quite thickly, not the decorative

stuff. First the zinc galvanizing was stripped off with hydrochloric acid,

then the copper and chrome plating were applied. The copper makes a

good base, and is very thermally and electrically conductive compared to

hardware store iron. Due to skin effect, the current in a high frequency

waveform flows mostly on the surface of the conductor, ignoring the bulk,

so the copper ought to make a difference. The chrome is there as it

is the hardest to evaporate metal we can electroplate.

Here are the separate pieces. As contact evaporation was a big concern

based on work with a prototype, the gap faces here were plated, first

with copper, and then with chromium, quite thickly, not the decorative

stuff. First the zinc galvanizing was stripped off with hydrochloric acid,

then the copper and chrome plating were applied. The copper makes a

good base, and is very thermally and electrically conductive compared to

hardware store iron. Due to skin effect, the current in a high frequency

waveform flows mostly on the surface of the conductor, ignoring the bulk,

so the copper ought to make a difference. The chrome is there as it

is the hardest to evaporate metal we can electroplate.The trigger electrode is a 10–32 screw with a sewing pin soldered into a hole drilled in the end. The sharp point will make it possible to trigger the gap with a relatively lower voltage. Sure is nice to have a machine shop, this was an easy part to make! As to the general machining, not that much was done. The caps had flats turned on the ends, were shortened, and tapped 3/8 x 16 to match the standard bolts. A flat was cut on one side to work with the washers for the trigger electrode. Not required, but nice. Once this is ready to go into real service, there will be a couple of holes drilled and tapped on the bottom, which will also get a flat, for mounting with nylon screws. If past experience means anything, this thing will try to come apart under the various forces involved. We only want that to happen when we desire it for maintenance.

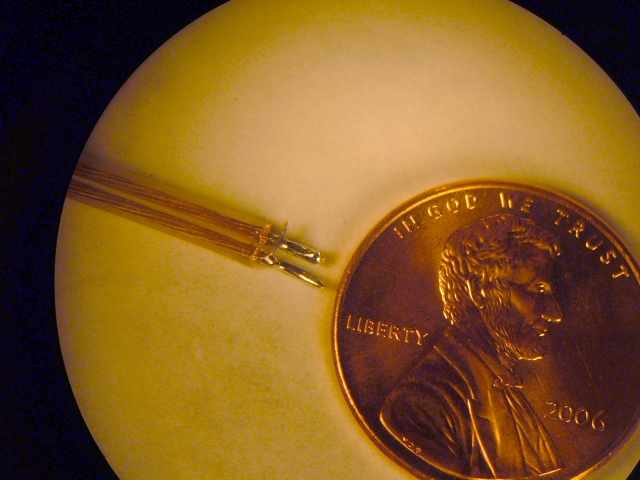

Here is an example of a miniature rail gun. This is just very cheap

speaker wire, stripped back about 1/4", tinned, and with one

conductor folded to short the beginning of the rails. In use, a blob

of PETN in nitrocellulose–based glue will cover the end of the

rails. This in turn can detonate a larger charge in a normal sized

blasting cap. You might be wondering how one can make 2500 Volts go

down this cheap wire. If you think about it, the voltage doesn't happen

until after all the action is over, and any residual charge in the capacitor

is wasted anyway. A huge current pulse is sent down

the wire, and the resulting magnetic field operates the rail gun, usually

vaporizing the projectile, which just does not matter to the

application, it still has the momentum and velocity to do the job, no

matter the form of matter. In previous tests, nearly the whole thing is

more or less

destroyed, and interesting holes appear in a witness plate placed downrange

a little from the end. This is a safety–glasses and hearing protector

sort of thing

when done indoors, but of course actual use will not be indoors, nor will

the user be very close by! In use, the main cable of course, is the

good stuff; the rail gun is only a couple of inches at the end of it.

We use 4 conductors of #10 for this. Regular romex works

fine too.

Here is an example of a miniature rail gun. This is just very cheap

speaker wire, stripped back about 1/4", tinned, and with one

conductor folded to short the beginning of the rails. In use, a blob

of PETN in nitrocellulose–based glue will cover the end of the

rails. This in turn can detonate a larger charge in a normal sized

blasting cap. You might be wondering how one can make 2500 Volts go

down this cheap wire. If you think about it, the voltage doesn't happen

until after all the action is over, and any residual charge in the capacitor

is wasted anyway. A huge current pulse is sent down

the wire, and the resulting magnetic field operates the rail gun, usually

vaporizing the projectile, which just does not matter to the

application, it still has the momentum and velocity to do the job, no

matter the form of matter. In previous tests, nearly the whole thing is

more or less

destroyed, and interesting holes appear in a witness plate placed downrange

a little from the end. This is a safety–glasses and hearing protector

sort of thing

when done indoors, but of course actual use will not be indoors, nor will

the user be very close by! In use, the main cable of course, is the

good stuff; the rail gun is only a couple of inches at the end of it.

We use 4 conductors of #10 for this. Regular romex works

fine too.The picture was taken through one eyepiece of our stereo microscope, at about 10x magnification. I am surely going to have to get a whiter light source for this, although it looks fine to the human eye as is. What I am using now is a pair of compact fluorescent lamps, which are warm white.